Welding

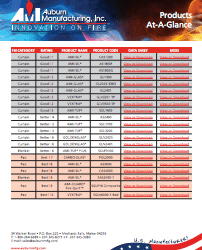

Click here to see all of our FM Approved Products-At-A-Glance along with their category, performance ratings, and data sheet and SDS information

Industry Leaders Providing Trusted Products World Wide.

Auburn Manufacturing Inc. (AMI) is the leading industry producer of FM Approved welding curtains, welding blankets and welding pads to protect people, plants, and equipment from heat, sparks, and molten metal in the workplace. Today we manufacture 21 certified high temperature fabrics (many times referred to generically as “welding blankets” or “fire blankets”) ranging in temperature resistance from 225°F (107°C) to 3000°F (1650°C).

AMI —The First To Meet FM ApprovalsWe were the first company in the world to have our hot work fabrics tested and approved by FM Approvals. We have maintained our Approval status since 2004. We continue to lead the way by offering the largest selection of certified, U.S. made, hot work fabrics for any kind of horizontal or vertical hot work procedure including welding, grinding, brazing, chipping, heat-treating or sand blasting. While other companies have followed our lead in getting their products third-party tested, none have as many choices as we do to meet any application.

Six Product Categories

- AMI-GLAS® – 100% fiberglass

- AMI-TUF® – Silicone-coated AMI-GLAS®

- VEXTRA® – Vermiculite-Coated AMI-GLAS®

- CARBO-GLAS® – Carbon-Fiberglass Composite

- GOLDENGLAS® – Neoprene-Coated AMI-GLAS®

- AMI-SIL® – Essentially Pure Amorphous Silica

Click on a fabric type to learn more about it, or click on a subcategory to see all products available. Or use the Product Search to locate products by specification.

Requirements for Third-Party Certification Safety professionals in industries such as shipbuilding, nuclear power generation, oil refining, mining, glassmaking and steelmaking now consider certified hot work fabrics a critical safety item. Certified welding curtains, blankets and pads must meet ANSI/FM 4950. The FM Approval Standard rates hot work fabrics by severity of use. The rating helps professionals determine which level of fire protection is needed for a specific hot work operation. Manufacturers of hot work products that meet this standard undergo and pass stringent testing, certification and ongoing audit procedures to meet the conditions for safety, performance and quality. In addition, manufacturers must maintain a quality control program and submit to manufacturing facility inspections as part of the Approval process.

For more information about our FM Approvals click here, and for a brief video presentation on the NFPA 51B Requirements for FM Approved Hot Work Fabrics click here. AMI Hot Work Fabrics Meet or Exceed Standards

AMI Hot Work Fabrics Meet or Exceed Standards

- MIL-C-20079H — Glass Cloth for thermal insulation components

- MIL-C-24576A — Cloth, Silica Glass for welding and cutting operations

- MIL DTL-24244D— Insulation Material with Special Corrosion, Chloride and Fluoride Requirements

- USCG164.009 — Test for Non-combustibility

- NRC 1.36 — Nuclear Regulatory Commission Standard

- US DOE Safety Rule 10 CFR 851 — Worker Safety and Health Program (for DOE and National Nuclear Security Administration)

- US DOE 1910.252 — OSHA Standard on Welding, Cutting and Brazing

- ANSI/FM 4950 — Standard for Evaluating Welding Pads, Blankets and Curtains for Hot Work Operations

- NFPA 51B, 2019 Edition — Standard for Fire Prevention During Welding, Cutting and Other Hot Work

- California Code of Regulations, Title 8, Section 4848 Fire Prevention and Suppression Procedures

- ANSI Z49.1 — Safety in Welding, Cutting and Allied Processes

- API 2009 — Safe Welding, Cutting and Hot Work Practices in the Petroleum and Petrochemical Industries

The NFPA 51B Standard — the one most often cited by both government agencies (OSHA, DOE) and private industry groups (API, AWS) for fire protection — now requires that welding curtains, blankets and pads be “Listed or Approved” (third-party certified) to ANSI/FM 4950. ANSI/FM 4950 is a new standard that tests and rates fabrics based on severity of use.

Buy Welding Blankets and Fire Quilt™ Products Online Now!

If you are not ready to buy, browse our samples page.

Call Customer Service at 1-800-264-6689 or Contact Us Today!

All 12 results for "Welding"Sorted by latest

Welding Categories

-

AMI-GUARD® Fire Quilt™

Quilted hot work curtain, blanket or pad.

Quilted composite with a fiberglass mat between two layers of fiberglass that has been coated with a specially formulated black silicone compound

-

AMI-GUARD® Fabricated Welding Curtains

Many of these fabrics are available as curtains, pads or blankets with or without grommets, custom sewn to fit your specific needs, or in standard sizes. Grommets are placed 18″ on center on all four sides. Standard thread is PTFE-coated fiberglass. Standard Sizes Available:

3′ x 3′, 6′ x 6′, 6′ x 8′, 10′ x 10′

-

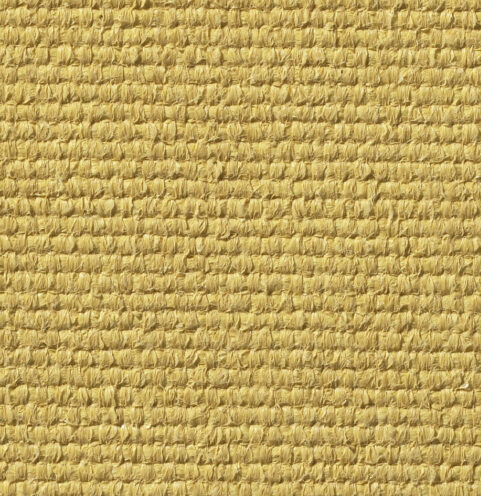

VEXTRA® (GLV) (GLV-TP) Cloth

100% fiberglass cloth coated with noncombustible vermiculite armor

-

AMI-TUF® PLUS (SGLP) Cloth

Fiberglass cloth with a silicone rubber coating compounded with proprietary mineral pigments

Rated to 500°F (260°C)

-

VEXTRA® (GLV-TP) Cloth

Fiberglass fabric coated with vermiculite

Rated at 1000°F and remains stable to 1500°F.

-

VEXTRA® (SGLV) Cloth

Heavy duty, heavy weight fiberglass treated with vermiculite and coated on one side with a silicone rubber compound.

Rated to 500°F (260°C).

-

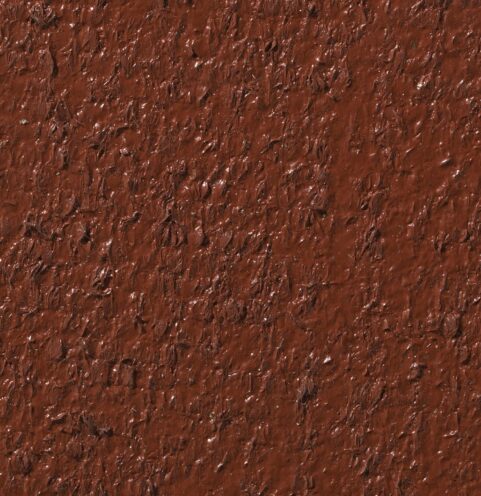

CARBO-GLAS® (PGL) Cloth

Advanced carbon fiberglass composite

Rated to 500°F (260°C).

-

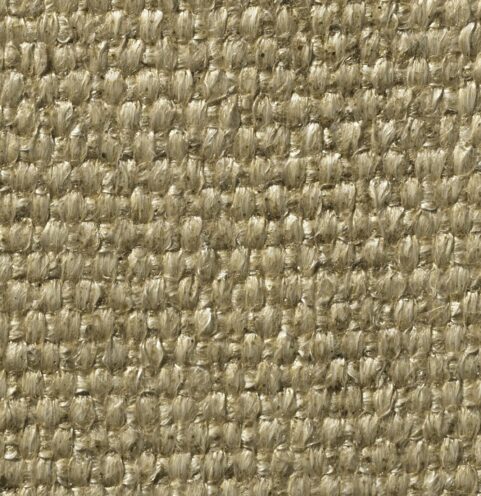

AMI-TUF® (SGL) Cloth

Silicone coated fiberglass cloth.

Good for outdoor use

Continuous operating temperature 500° F (260ºC)

SGL1700 meets the requirements of ASTM C1695-09

SGL1700 and SGL3200 meets NFPA 701-1999.

-

GOLDENGLAS® (GLN) Cloth

100% fiberglass cloth coated with a tough, neoprene rubber

Rated to 225°F (107°C).

-

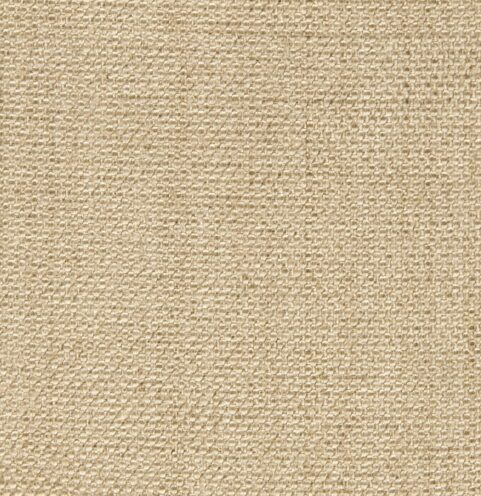

AMI-GLAS® (GL) Cloth

Ideal for vertical spark protection typically found in light welding applications.

Rated to 1000°F (540°C).

All uncoated fiberglass yarns meet USCG 164.009 “Test for Incombustibility”

GL2025-9383 meets the requirements of ASTM C1695-09 and MIL C 20079H Type 1 Class 9

-

AMI-SIL® (SAS) Cloth

96% silica (minimum) cloth with a cured silicone rubber on one side

Rated to 1800°F (980°C)

-

AMI-SIL® (CAS) (AS) Cloth

Minimum 96% pure amorphous silica cloth

Rated to 1800°F (980°C).

AS1800G & AS3600 meet USCG164.009 as part of MIL-C-24576SH and meet NFPA 701/1999 Method 2.

AS3600 and CAS4000 are rated as a PAD, all other are CURTAINS