Search results: “aluminized”

AMI manufactures the widest range of versatile, heat resistant fabrics for demanding high heat MRO applications to reduce the risk of fire and heat, protect personnel and equipment, lower energy consumption, and save money. All our high heat fabrics and fire retardant textiles are available in a variety of high-performance fibers and composites including aramid, fiberglass and essentially pure amorphous silica. They are light, flexible and versatile, making them easy-to-use for hundreds of extreme heat applications.

AMI manufactures a complete line of standard fiberglass, silicone-coated and WETWRAP™ re-wettable encapsulation cloth.

AMI-GLAS® Wetwrap™ insulation cloth is made of 100% fiberglass fabric and is coated with a specially formulated inorganic coating, which develops tack and bonds to itself when wet. Also known as “re-wettable cloth,” this product provides a safe, heat resistant textile covering for more fragile insulation materials.

Applications include:

- Pipe lagging

- Expansion joints

- Heat shields

- Machinery protection

- Insulation pads for removable flanges and valve covers (See Pad components for more info)

Call Customer Service at 1-800-264-6689 or Contact Us Today!

All 8 results for "Heat Resistant Cloth"Sorted by latest

MRO Categories

-

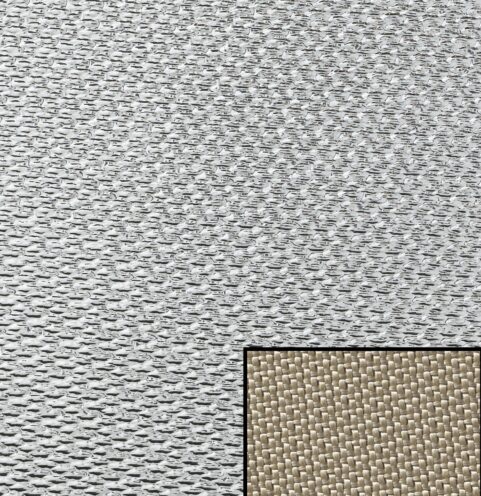

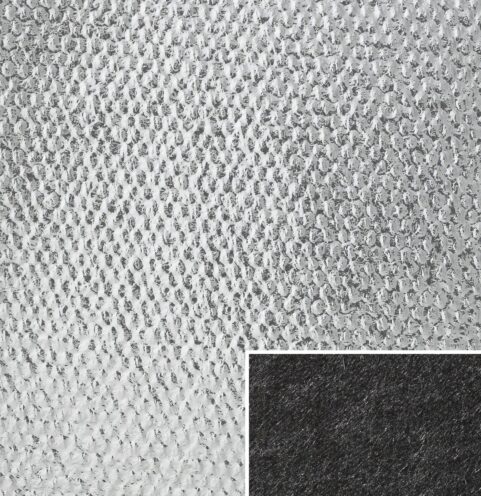

AMI-SIL® (AAS) Aluminized Cloth

AMI-SIL® (AAS) is a very high heat resistant fabric made with 96% amorphous silica with an aluminized or metalized polyester film laminated to one side. Aluminized AMI-SIL fabrics are as attractive as they are effective against extreme radiant heat. AMI-SIL (AAS) is rated to 450°F (232°C). Sample available in Aluminized Cloth 25 oz and 37 oz only….

-

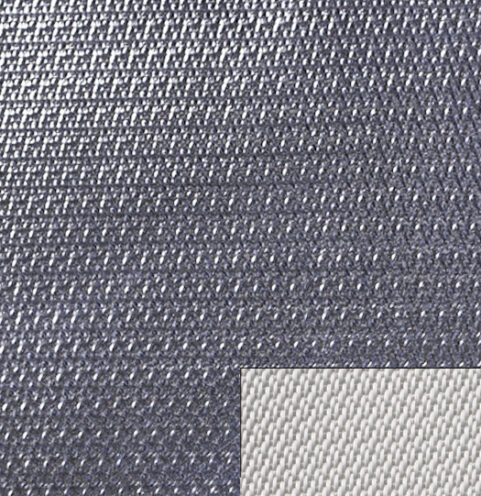

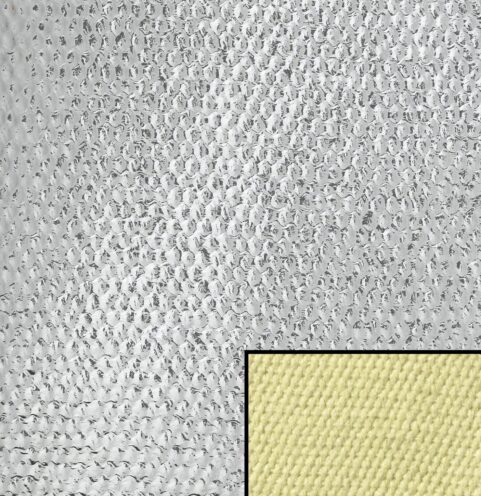

AMI-GLAS® (AMGL) Aluminized P.E.T Cloth

AMI-GLAS® is a 100% fiberglass textile with an aluminized polyester film laminated to one side. For mid-range temperature applications or for applications when radiant heat is encountered aluminized AMI-GLAS is a good choice. AMI-GLAS (AGL) is rated to 450°F (232°C). Sample available in AMGL 1300 Cloth 16oz only….

-

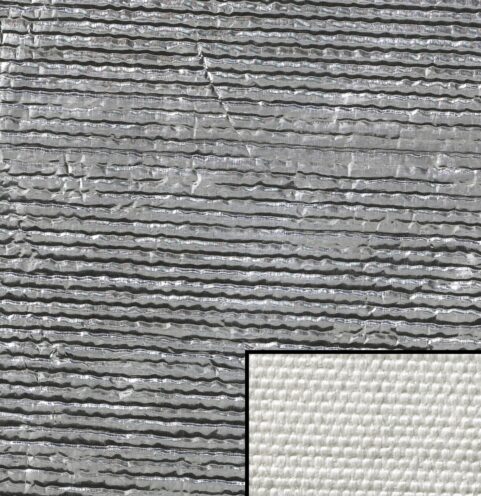

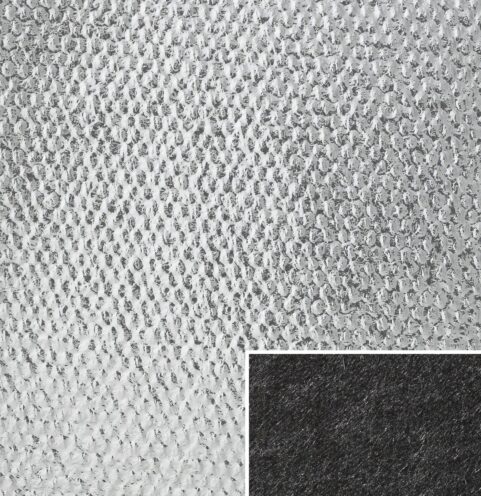

AMI-GLAS® (AGL) Aluminized Cloth

AMI-GLAS® (AGL) is made of 100% continuous filament fiberglass with an aluminum foil lamination on one side. Unlike a metalized film, this lamination is done with a .001” aluminum foil for overall temperature resistance. The foil is designed to stay intact even after exposure to direct heat. A ravel-resistant coating can be applied to one side to further enhance die-cutting operations. AMI-GLAS (AGL) is rated to 450°F (232°C). Sample available in AGL2025-9383 21 oz only….

-

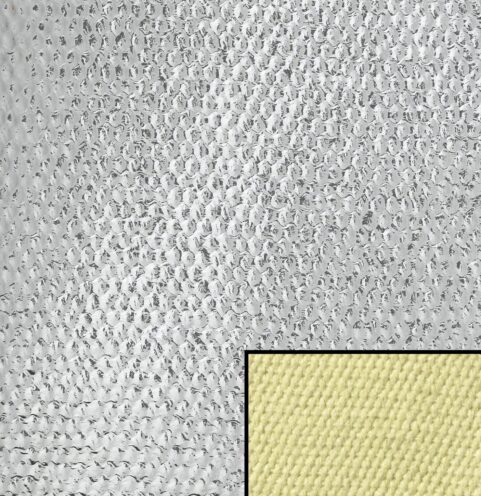

AMI-FLEX® (AFL) Cloth

AMI-FLEX® (AFL) is made of aramid fibers with fiberglass support and then laminated on one side with a special aluminized polyester film making it the ideal cloth for heat resistant safety clothing. Our aluminized AMI FLEX is as attractive as it is effective for mid-range temperature applications. AFL1700 meets ASTM F 1939 and ASTM 955-07…

-

CARBO-FLEX® (AFLPN) Cloth

AMI’s heat resistant textile—CARBO-FLEX® (ALFPN)—is a composite of a woven fabric, a non woven material and a layer of aluminized polyester film for reflectivity. It provides continuous protection up to 600°F (320°C). Safety apparel made with AMI’s aluminized CARBO-FLEX has additional protection against exposure to radiant heat. AFLPN1500 meets ASTM F 1939 and ASTM 955-07 …

-

AMI-FLEX® (AFL) Cloth

AMI-FLEX® (AFL) is made of aramid fibers with fiberglass support and then laminated on one side with a special aluminized polyester film making it the ideal cloth for heat resistant safety clothing. Our aluminized AMI FLEX is as attractive as it is effective for mid-range temperature applications.

-

AMI-FLEX® (AFLPN) Cloth

AFLPN is a composite of a woven fabric, a non-woven material and a layer of aluminized polyester film for reflectivity. It provides protection up to 600°F (320°C). Safety apparel made with AMI’s aluminized CARBO-FLEX has additional protection against exposure to radiant heat….

-

AMI-GLAS® (AGL) Cloth

AMI-GLAS® (AGL) is a 100% fiberglass fabric with an aluminized lamination which makes it ideal for spray shield applications. Unlike a metalized film, AMI’s lamination is done with a .001” aluminum foil for overall temperature resistance. The foil is designed to stay intact even after exposure to direct heat. A ravel-resistant coating can be applied to one side to further enhance die-cutting operations. AMI-GLAS® (AGL) is rated to 300°F. The temperature limitation reflects the limitation of the adhesive used for aluminization….